DMS combines depth of experience with rigorous inspection and advanced diagnostic capability to solve complex operational challenges and provide insightful recommendations to help customers achieve their goals. DMS is one of the leading propulsor/propeller repair facilities in the world with over 30 years of propeller repair experience. We provide innovative propeller and impeller repair, specialized propulsor repair, testing and prototyping.

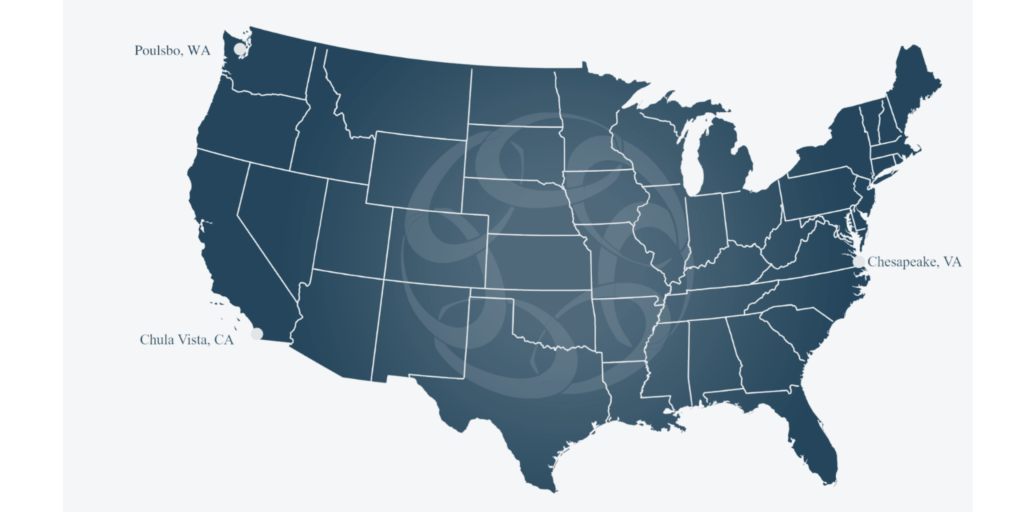

With strategically placed repair facilities on both the east and west coast and the capability for in-situ repairs, DMS is ready to assist anytime, anywhere!

Our Capabilities

- Welding

- Machining

- Cleaning/Polishing

- Static and Dynamic Balancing

- Hot and Cold Straightening

- Blade Surface Gage Fitting

- Blade Pitching

- Eye Bolt Hole Repairs

- Prairie Air Channel Repair

- Hub Bore Repair

- Advanced Metrology

- Stress Relieving

- NDT Services

- AMPP Blasting and Painting

- Packaging and Preservation

Certifications & Qualifications

ISO 9001-Quality, 14001-Environmental, and ISO 45001-Health & Safety

ABS/NAVSEA Weld Qualifications

DNV and Lloyds as needed

NAVSEA Certified Visual Technical Inspectors

NAVSEA Certified Dimensional Inspectors

NAVSEA Certified Ducted Propulsor Inspectors

NDT (VT, PT, MT, and UT) Certified Employees

Welding Capabilities

Using experimental welding techniques, DMS’s weld engineers are able to evaluate new equipment and materials. Data collected during experimental welding trials is evaluated and used to develop process improvements in the welding field. Certification tests are conducted on weld procedures and process improvements to ensure they meet specific program and customer requirements.

Weld operators are certified to inspect welds using various nondestructive testing methods including, ultrasonic testing, liquid penetrant testing, magnetic particle testing, and visual technical inspection.

• DOD-STD-2185 – Requirements for Repair and Straightening of Bronze Naval Ship Propellers.T9074-AQ-GIB-010/248 – Requirements for Welding and Brazing Procedure and Performance Qualification.

• T9074-AR-GIB-010/278 – Requirements for Fabrication Welding and Inspection, and Casting Inspection and Repair for Machinery, Piping, and Pressure Vessels.

• ABS rules for survey after construction – 2012 Part 7 Section 10 Guide for Bronze and Stainless-Steel Propeller Castings.

• AWS D1.1 Structural Welding Code – Steel.

• Lloyds Register Rules and Regulations – 2015.